Why do Automotive Connector Seals decide whether your harness passes first time?

2025-11-26

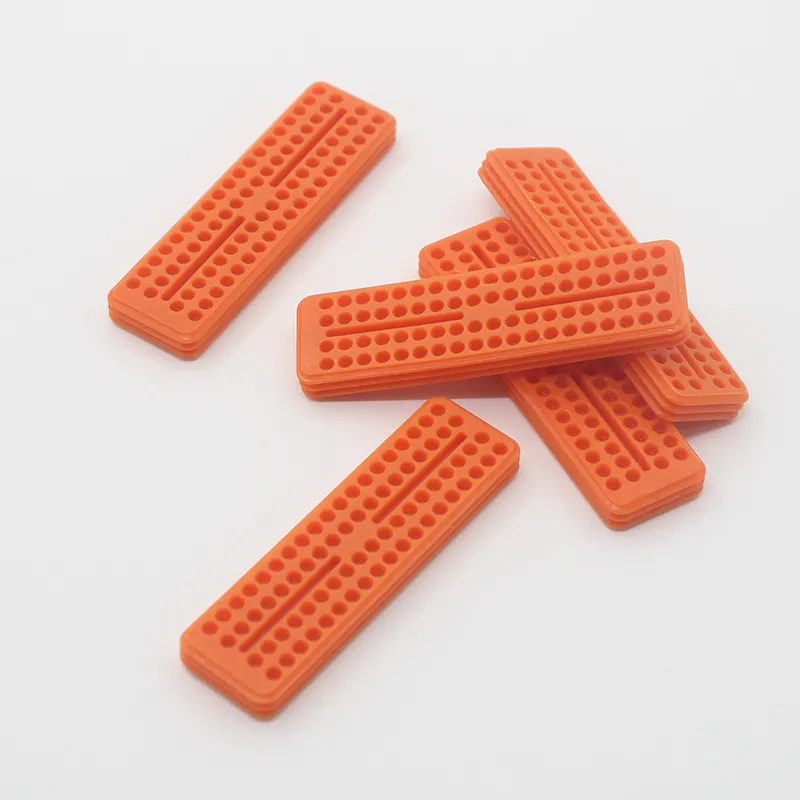

I have shipped enough wiring sets to know one quiet truth: connectors don’t fail loudly, they fail slowly. That is why, on projects where reliability matters, I bring in partners like Guoming Rubber early and design around Automotive Connector Seals from day one. Done right, the seal becomes the invisible insurance policy behind stable electrics, clean signals, and fewer reworks on the line.

What real-world failures do Automotive Connector Seals actually prevent?

- Moisture creep that corrodes terminals and drives up contact resistance over seasons, not days.

- Dust and road grit that turn micro-fretting into intermittent CAN or sensor faults.

- Pressure wash or splash events that momentarily flood cavities, then trap water where it hurts most.

- Thermal cycling that squeezes out poorly selected elastomers and leaves gaps at the wire entry.

- Vibration that hammers a marginal interface until the seal lips lose contact.

Well-specified single-wire seals and cavity plugs exist for exactly these threats, and when they fit the wire and cavity correctly, they keep contaminants out and connections stable over time.

Which material should I choose and why?

I do not guess material; I map environment and fluids, then pick the compound. For Automotive Connector Seals, the short list is familiar—silicone, fluorosilicone, EPDM, and NBR—yet each behaves differently under heat, cold, and chemicals. The quick matrix below is how I frame the trade-offs before I request samples and data sheets:

| Material | Typical temperature window | Fluid resistance | Best for | Trade-offs |

|---|---|---|---|---|

| Silicone | Wide range for cabin to engine-bay duty | Good general resistance; not ideal for fuels | Thermal cycling, UV exposure, flexible seals | Can swell in oils/fuels if not fluorinated |

| Fluorosilicone | Commonly quoted from very low to high extremes | Excellent vs oils, fuels, hydraulic fluids | Fuel system connectors, under-hood sensors | Higher material cost vs standard silicone |

| EPDM | Robust for weathering and outdoor duty | Strong vs water/steam; weak vs hydrocarbons | Body, chassis, high-humidity or splash zones | Not for oil/fuel exposure |

| NBR | Serviceable in moderate temps | Good vs oils and many greases | Powertrain auxiliaries away from hot zones | Weather/ozone resistance lower than EPDM |

If I expect fuel or aggressive fluids, I step up to fluorosilicone; it blends silicone’s thermal stability with chemical resistance and is a proven choice in automotive fuel and hydraulic areas. For weather-exposed connectors, EPDM’s ozone and UV resilience win.

How do I size and validate a seal without guesswork?

- Match the wire OD to the seal ID:I confirm strip length and final insulation OD after crimp, then choose the seal’s inner diameter for elastic interference—not brutal compression that nicks insulation.

- Check cavity geometry:I verify the groove width, depth, lead-in chamfers, and any anti-over-insertion features so the seal lips sit where the connector actually supports them.

- Control compression set:I request compound data and run cycling tests that simulate weekly thermal swings; the goal is elastic recovery after heat soak.

- Validate ingress protection:For exterior connectors, I test to the required IP target—IP67 immersion is a common benchmark—and inspect for post-test corrosion or water tracks at the wire entry.

- Audit assembly reality:I watch operators: lubrication, insertion force, and any tendency to twist or roll the seal tell me if the design will hold up on a line running three shifts.

On projects where I’ve specified Automotive Connector Seals with IP-rated performance and high tear strength, long-term stability improved and field returns dropped—proof that validation beats assumptions.

Where do Automotive Connector Seals deliver outsized value in EV and ADAS?

- Three-electric systems:Battery, drive, and control electronics run through harsh thermal and vibration profiles; the right elastomer guards against transient leaks that can trip diagnostics.

- Sensor density:More cameras, radars, and lidars mean more connectors in splash, salt, and grit—seals keep signals clean and service intervals predictable.

- Lightweighting:As housings get thinner, the seal carries more of the environmental load; better compounds offset the margin lost in plastics.

In practice, these zones see the toughest combination of moisture, dust, and shock, so material targeting per location is non-negotiable.

What advantages do I get from a custom seal partner instead of catalog parts?

- Geometry that fits your connector:Lip designs and wire-entry tapers tailored to your cavity reduce assembly force and prevent roll-over.

- Compound tuned to environment:Silicone for thermal cycling, fluorosilicone for fluids, EPDM for weather—picked with test data, not lore.

- Process control:Vulcanization windows and hardness consistency keep seal compression predictable from PPAP to mass production.

- Lifecycle support:Drawing control, retention samples, and refresh plans protect your change management through model years.

Teams like Guoming Rubber publish practical selection guidance for temperature, moisture, and chemical exposure and back it with lab data, which shortens my sampling loop and de-risks launch.

What design traps still catch engineers and buyers?

- Picking the wire seal by AWG instead of actual finished OD after crimp and over-mold.

- Reusing a legacy seal in a cavity with different lead-in or groove width “because it almost fits.”

- Specifying a fuel-area connector with non-fluorinated silicone “since it passed the water test.”

- Skipping compression-set testing and discovering post-soak leakage near SOP.

- Ignoring operator feedback on twist/roll during insertion until yield drops on night shift.

What do I include in my RFQ so suppliers quote fast and accurately?

- Connector family and cavity drawing with tolerances and groove detail.

- Target IP rating and test method, expected pressure wash or immersion profile.

- Wire part number and finished OD at the seal location after crimp/over-mold.

- Environmental map:temperatures, chemicals, splash zones, UV exposure.

- Annual volume, color requirements, packaging, and any lube or assembly aids allowed.

When I add this detail, quotes come back cleaner, sampling starts sooner, and the first-article results align with what production can actually build.

Why am I confident recommending Automotive Connector Seals from a specialist?

Because the data and field results keep lining up: seals built for automotive duty, validated to waterproof performance, and molded with consistent hardness and tear resistance keep electrical systems stable longer. That is exactly the philosophy I see reflected in serious manufacturers’ product lines and application notes. Share your drawings and constraints, or contact us with your wire OD, cavity geometry, fluids, temperature range, and target IP rating. I will respond with material recommendations, a sampling plan, and a fast path to validation. If you have an active project and need pricing or PPAP timing, send an inquiry now—contact us to request a quote and lock in your testing window today.