Why Is a Brazed Diamond Grinding Wheel the Go To Choice for Precision and Tough Materials?

2026-01-04

When I first started working with advanced grinding solutions, I quickly realized that not all wheels are built for real-world pressure. Over time, through hands-on use and customer feedback, I found myself consistently returning to one solution that simply performs. That is where Jianyue naturally entered the picture, especially through its flagship Brazed Diamond Grinding Wheel. Not because of marketing claims, but because it solved problems that machinists and fabricators face every single day.

What Makes a Brazed Diamond Grinding Wheel Different from Conventional Options?

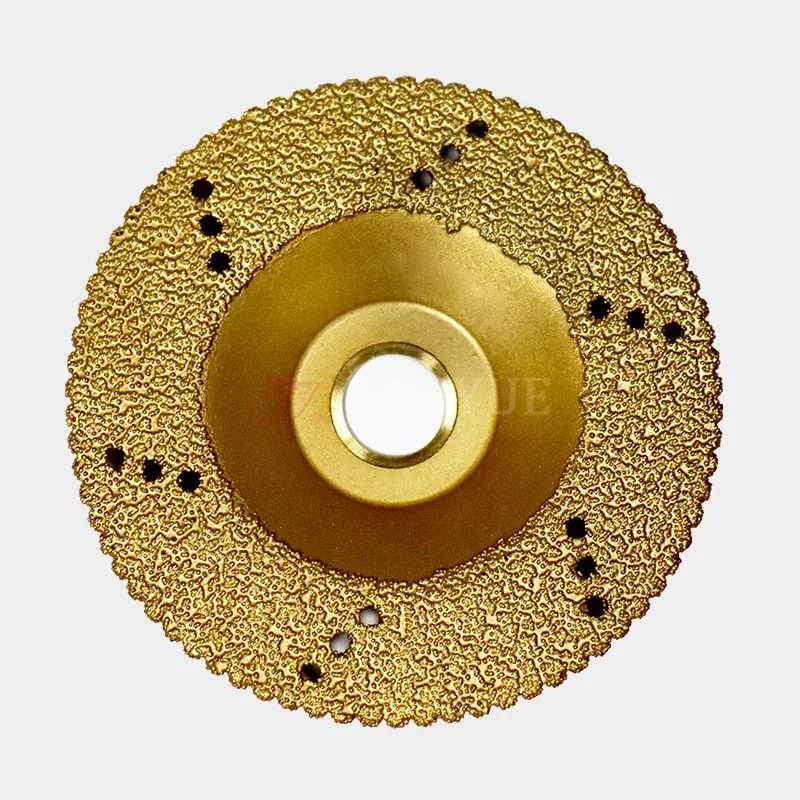

In my experience, the biggest frustration with traditional grinding wheels is inefficiency. They wear out too fast, clog easily, and lose cutting ability under heat. A Brazed Diamond Grinding Wheel takes a completely different approach. Instead of embedding diamond grains deep inside a bond that slowly releases them, brazing fixes each diamond particle firmly onto the wheel surface.

This structure means more exposed cutting edges, sharper engagement with the workpiece, and far less wasted energy. I have seen this make a noticeable difference when grinding hard materials like stone, ceramics, glass, and carbide.

Why Do Professionals Care About Cutting Efficiency and Heat Control?

Grinding is rarely just about removing material. It is about control. Excessive heat can damage surfaces, distort dimensions, and shorten tool life. One reason I trust a Brazed Diamond Grinding Wheel is its open structure, which allows better airflow and chip removal.

- Faster material removal without aggressive pressure

- Lower grinding temperature during continuous operation

- Cleaner surface finish with reduced burn marks

From a productivity standpoint, this translates into fewer passes, less downtime, and more predictable results.

How Does a Brazed Diamond Grinding Wheel Perform Across Different Materials?

I often get asked whether one wheel can handle multiple materials without compromise. Based on field use, the answer is yes, within reason. A well-designed Brazed Diamond Grinding Wheel shows impressive versatility.

| Material Type | Performance Observation | User Benefit |

|---|---|---|

| Granite and Marble | Stable cutting with minimal edge chipping | Smoother finish and less rework |

| Glass and Quartz | Controlled grinding without cracking | Higher yield on fragile materials |

| Ceramics | Consistent removal rate | Improved dimensional accuracy |

| Carbide Tools | Sharp cutting action | Extended tool life |

This adaptability is one of the reasons a Brazed Diamond Grinding Wheel is often chosen by workshops that cannot afford to switch tools constantly.

What Practical Advantages Matter Most in Daily Operations?

From my point of view, theory only matters if it translates into daily benefits. The practical strengths of a Brazed Diamond Grinding Wheel become clear after extended use.

- Longer service life compared to resin-bond wheels

- No dressing required during normal operation

- Stable performance even under heavy loads

- Reduced vibration for better operator comfort

These are not abstract advantages. They directly affect cost control, output quality, and operator confidence.

How Does Jianyue Approach Quality and Consistency?

What sets Jianyue apart for me is not a single feature, but consistency. Each Brazed Diamond Grinding Wheel reflects careful control over diamond selection, brazing temperature, and wheel balance. This matters because uneven brazing or poor diamond placement can lead to unpredictable wear.

In actual use, that consistency shows up as smoother grinding, fewer surprises, and a product that behaves the same from the first job to the last.

When Is a Brazed Diamond Grinding Wheel the Right Investment?

I usually recommend a Brazed Diamond Grinding Wheel when users are dealing with hard or brittle materials, tight tolerances, or high-volume work. While the initial cost may be higher than basic wheels, the return becomes obvious over time.

- Less frequent wheel replacement

- Lower labor time per job

- Reduced risk of material damage

In environments where precision and reliability matter, the investment pays for itself.

Are You Ready to Improve Grinding Efficiency and Surface Quality?

If you are tired of inconsistent results, excessive heat, or short tool life, it may be time to reconsider your grinding solution. A well-engineered Brazed Diamond Grinding Wheel can change how your operation performs on a daily basis.

I encourage you to reach out and learn more about how Jianyue solutions can match your specific application. Contact us today to discuss your requirements, request technical support, or get a customized recommendation. A simple conversation could be the first step toward more efficient and reliable grinding.