Why Is a High-Precision Speedometer Tester Becoming the Key Standard for Vehicle Safety?

2025-11-21

A speedometer tester is a specialized diagnostic instrument designed to measure, verify, and calibrate the accuracy of a vehicle’s speed display. As modern transportation shifts toward higher safety standards, more stringent inspection protocols, and increasing digitalization of vehicle systems, the demand for advanced speedometer testing technology continues to rise.

The discussion unfolds into four comprehensive sections, addressing product functionality, industry problems, technical innovations, and future development directions. A detailed parameter list is also provided to ensure clarity for engineers, procurement specialists, and automotive professionals seeking a dependable solution.

What Key Features Shape a High-Performance Speedometer Tester?

Vehicle speed measurement devices must adhere to strict accuracy requirements. A high-quality speedometer tester not only measures speed values but also validates the response consistency, repeatability, and compliance of various vehicle categories—from motorcycles to passenger cars and commercial vehicles.

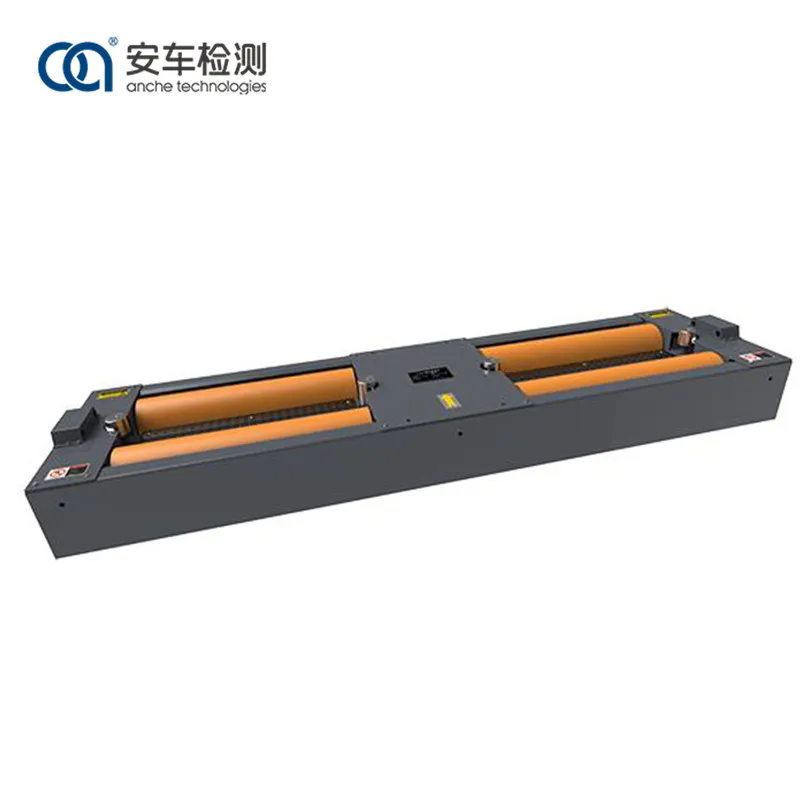

Below is a structured specification overview for a professional Speedometer Tester tailored for automotive workshops and testing laboratories:

Product Parameters (Example Specification Table)

| Parameter Category | Specification |

|---|---|

| Measurement Range | 0–300 km/h (precision range adjustable) |

| Accuracy Tolerance | ±0.2% FS or better |

| Display System | 7–10 inch industrial-grade LCD panel |

| Compatible Vehicles | Motorcycles, passenger cars, light trucks, commercial vehicles |

| Sensor Interface | Optical, magnetic, Hall-effect, and digital encoder compatibility |

| Power Supply | AC 110–240V / 50–60Hz |

| Data Output Functions | USB export, RS232/RS485, optional wireless module |

| Test Bench Material | High-strength alloy steel with corrosion coating |

| Durability Standard | Tested for 1,000,000+ operation cycles |

| Safety Features | Overload protection, automatic stop control, anti-slip roller surface |

| Software System | PC-based analysis platform with calibration certificate generation |

| Operation Mode | Automatic, semi-automatic, and manual testing options |

This structured parameter list highlights the technical completeness needed for laboratory-grade measurement and ensures the tester supports both analog and digital speedometer systems—critical as vehicle electronics become increasingly complex.

Why Do Automotive Facilities Need a Speedometer Tester?

Speed measurement impacts multiple dimensions of road safety, regulatory compliance, and user trust. As transportation authorities tighten inspection systems, workshops and inspection stations face growing pressure to ensure speedometer accuracy across a wide variety of vehicles.

Why Speedometer Accuracy Matters

-

Legal Compliance: Many countries mandate annual or biannual inspection of speed measurement systems, especially for commercial and public transportation fleets.

-

Accident Prevention: Accurate speed readings directly influence a driver’s ability to react safely and prevent collisions.

-

Consumer Trust: Vehicle owners rely on workshops to provide reliable diagnostic results for speed-related electronic systems.

-

Fleet Management: Fleet operators use calibrated speed data to optimize routes and reduce fuel consumption.

Why Traditional Testing Methods Fall Short

-

Manual or analog tools lack the precision required for digital dashboards.

-

Older bench platforms cannot interface with modern encoder-based sensors.

-

Data recording is often incomplete, complicating certification for regulatory audits.

-

Mechanical wear and environmental interference reduce measurement repeatability.

A modern speedometer tester solves these challenges through automated calibration processes, advanced sensor interpretation, high-accuracy digital measurement, and real-time reporting.

How Does a Professional Speedometer Tester Improve Testing Efficiency and Reliability?

High-end speedometer testers are engineered to streamline the work of technicians while increasing testing accuracy.

How the Testing Process Works

-

Vehicle Placement: The wheels or transmission output are connected to the testing bench or sensor interface.

-

Signal Capture: The tester reads rotational speed, signal frequency, or encoder pulses.

-

Data Conversion: The system translates pulses into a standardized km/h or mph value.

-

Comparison: Speed readings from the vehicle’s own speedometer are compared to tester output.

-

Adjustment: If deviations occur, technicians calibrate the vehicle’s internal system.

-

Report Generation: A certified digital report is produced for inspection or customer records.

Core Functional Advantages

-

High-Speed Stability: Ensures consistent measurement even at high rotational speeds.

-

Multi-Sensor Support: Allows testing for both old-generation mechanical cables and modern CAN-BUS digital systems.

-

Automatic Calibration Routines: Reduces technician workload while improving accuracy.

-

Long-Term Reliability: Industrial components guarantee long-term use without drift or degradation.

-

Data Archiving: Essential for inspection authorities or enterprise fleet audits.

What Applications Benefit Most?

-

Automotive inspection centers

-

Dealership service departments

-

Independent repair workshops

-

Vehicle R&D labs

-

Technical schools and training institutions

-

Fleet management companies

These environments require a balance of durability, precision, ease of operation, and digital integration—all pillars of a professionally engineered speedometer tester.

How Will Speedometer Testing Evolve with Intelligent Transportation Systems?

Vehicle speed measurement is rapidly changing as digital dashboards, ADAS systems, and automated driving technologies mature. The role of speedometer testers will expand in several directions:

1. Integration With Digital Vehicle Networks

Modern speed sensors increasingly rely on CAN, LIN, and Ethernet communication. Testers must decode these signals accurately while offering firmware upgrades for evolving standards.

2. Cloud-Based Certification and Reporting

Cloud synchronization allows inspection centers and fleet operators to store calibration certificates securely and access them from any location.

3. AI-Enhanced Analysis Models

Predictive analytics will identify early signs of sensor drift and recommend maintenance before accuracy issues occur.

4. Multi-Vehicle Intelligent Adaptation

Future testers may automatically detect the vehicle model, sensor type, and calibration settings, reducing technician input.

5. More Environmentally Robust Test Platforms

With transportation expanding into high-humidity, low-temperature, and high-dust regions, the mechanical durability of the tester will continue to evolve.

6. Integration With Autonomous Systems

As autonomous vehicles require extremely precise speed data for control algorithms, test accuracy requirements will become stricter, pushing testers toward ±0.1% FS or better.

The future of speedometer testing will be a blend of digitalization, automation, and predictive maintenance—driven by global safety regulations and advanced vehicle architectures.

Common Questions About Speedometer Testers

Q1: How often should a vehicle undergo speedometer testing?

A1: For private vehicles, testing intervals typically follow local inspection cycles, generally once every 1–2 years depending on government regulations. Commercial vehicles, taxis, and buses may require more frequent testing due to intensive usage. Workshops also recommend recalibration whenever the vehicle undergoes significant repairs involving the transmission system, wheel configuration changes, or speed sensor replacement.

Q2: What causes a speedometer to display incorrect speed?

A2: Inaccuracies usually stem from worn sensors, damaged speedometer cables, electronic control module malfunctions, altered tire sizes, or misconfigured digital dashboards. Environmental conditions such as vibration, moisture, and electromagnetic interference can also distort signal readings. A professional speedometer tester helps identify the root cause by isolating mechanical, electronic, and sensor-related factors.

Why Choosing the Right Speedometer Tester Strengthens Professional Automotive Services

In the evolving world of vehicle diagnostics, a speedometer tester stands as a critical instrument that shapes road safety, workshop reliability, and regulatory compliance. As vehicle technology grows more sophisticated, the requirements for accuracy, digital compatibility, and data management become even more demanding. A professional testing system not only ensures operational credibility but also enhances service efficiency and customer confidence.

Brands such as Anche continue to develop precise, durable, and user-friendly speedometer testing solutions that meet global standards and align with future automotive trends. For facilities seeking to strengthen their testing capabilities or upgrade to next-generation diagnostic equipment, professional consultation can clarify which model best matches operational needs.

For more professional guidance or product inquiries, feel free to contact us.